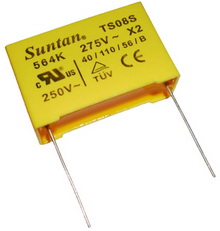

Suntan Plastic Film Capacitors----TS08S

Suntan Technology Company Limited was founded as professional manufacturer of Plastic Film Capacitor.

The features of Plastic Film Capacitor are non-inductive construction, self-healing, high reliable and superior performance in high frequency applications.

It is applied to filter and noise suppression circuit, pulse logic and timing circuit, DC blocking, by-passing and signal coupling in general communication equipment. The construction of Plastic Film Capacitor includes polyeser film dielectric with vacuum-evaporated metal electrodes, radial leads of tinned wire are electrically welded to the contact metal layer on the ends of capacitor winding, expoxy resin coating.

Are you interested in learning more details about Plastic Film Capacitor.Please contact us now!

Email:sales@suntan.com.hk

Website:http://www.suntan.com.hk/Plastic-Film-Capacitors/TS08S.html